Steeped in history, We’ve been malting since the late 1600s.

See how French & Jupps evolved alongside key global events over the past 300 years

At the Maltings, we have a stunning collection of artefacts and antiques from our past.

by 1689

The Jupp family were farmers and maltsters on the South Downs in West Sussex.

1750

Construction work started on the current Maltings premises.

1774

David Jupp, one of the few privately owned maltsters in the south of England, was producing malt at Kingston-upon-Thames and Spitalfields in London.

1780

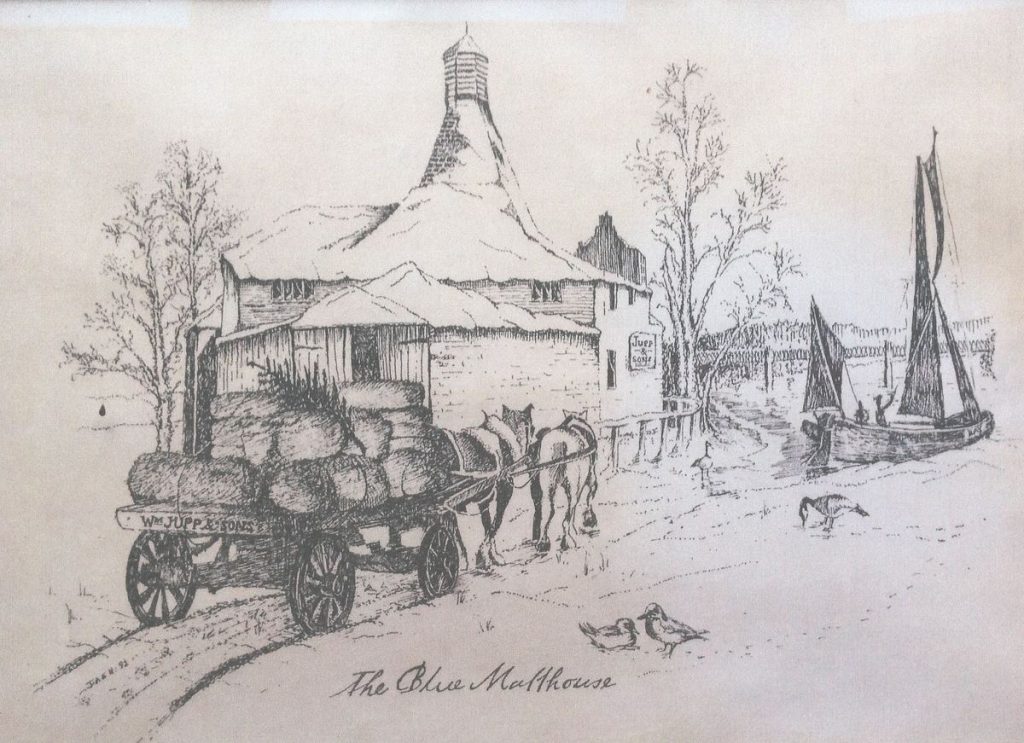

William Jupp was occupying a single malthouse in High St, Old Brentford, Middlesex.

There was a trading relationship with William Whitbread’s brewing, distilling and rectifying business in Old Brentford.

IN THE USA ~ Following extensive damage during the 1812 War, President James Madison commences a three year re-build of The White House to restore it to the magnificent building we know today.

INVENTION ~ A British inventor, Daniel Wheeler invented a device for roasting malt and kilning. This new and improved method introduced a rotating drum, which replaced the perforated floor kiln, preventing the malt from being exposed to the kiln’s fire. Thus maltsters could now control the flavour and colour of malts with more precision.

1826-7 & 1839

At Kew Bridge House, the Jupp family were operating a malthouse on the site in 1826–7 and 1839. They were the leading 19th-century maltsters of Brentford.

1842

In the UK, roasting was first permitted as a result of the ‘Roasted Malt Act’ of 1842, which stated that : “malt is not to be roasted for sale, or sold, except by persons duly licensed”. The special licence, or patent, led to the products being referred to as ‘patent malts’. ‘Speciality malts’ was another epithet applied to them, and the manufacture of such products has always required intensive energy usage, capital investment, technology, highly skilled and experienced supervision and quality control.

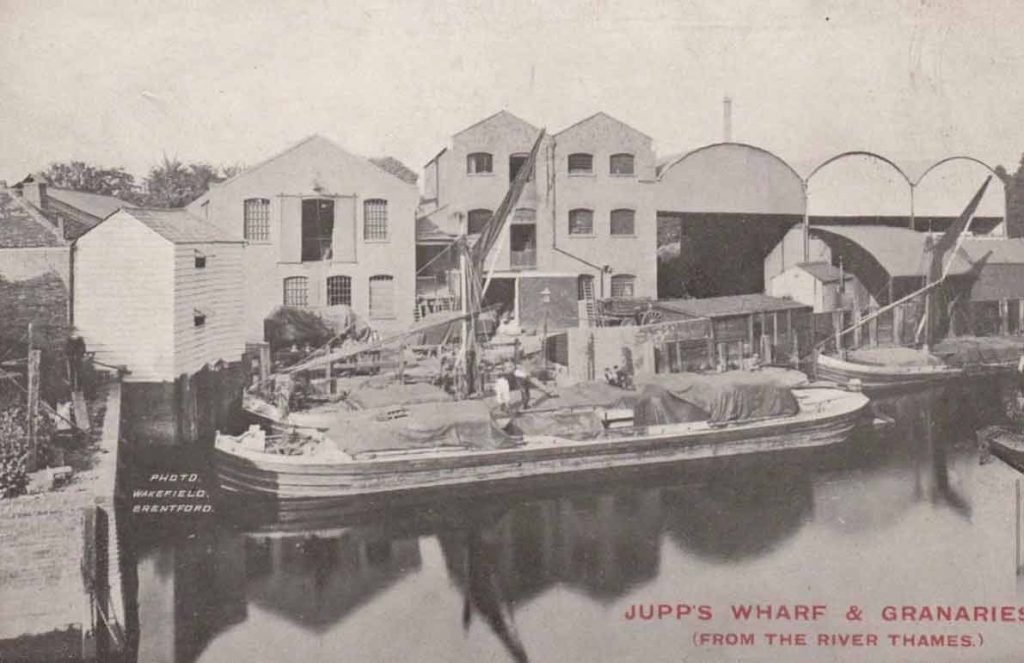

The Jupp family leased a malt house at the Strand on the Green, by the Thames at Kew Bridge. They also operated Jupps Wharf at the end of the Grand Union canal.

1848

William Jupp was a partner with Edward Wilks and Matthew Henry Cowell as brewers in St Georges Road, Southwark.

Mid 1800s

Malt was being supplied by the Jupps business to Samuel Whitbread and Benjamin Truman. This was taken up to Tower Bridge by sailing barge. The then carrier was a local farmer called Margaret French.

William Jupp bought the freehold malting on either side of the River Lea in Stanstead Abbotts, Hertfordshire.

One was River Mead Maltings on the Stanstead St Margarets side of the river, just behind the Jolly Fisherman pub and the other was the Rose and Crown maltings on the opposite side of the river, which is still in use today.

The Maltings was auctioned in 1864 at the Saracen’s Head Inn on Ware High Street (a neighbouring town)

1867

The business relationship between the Jupp family and Margaret French was so successful that she was taken into partnership. In the same year, the firm opened a roasting plant in Bell Lane, close by Liverpool Street station, due to the increased demand for dark malts (mainly for London Porter).

1881

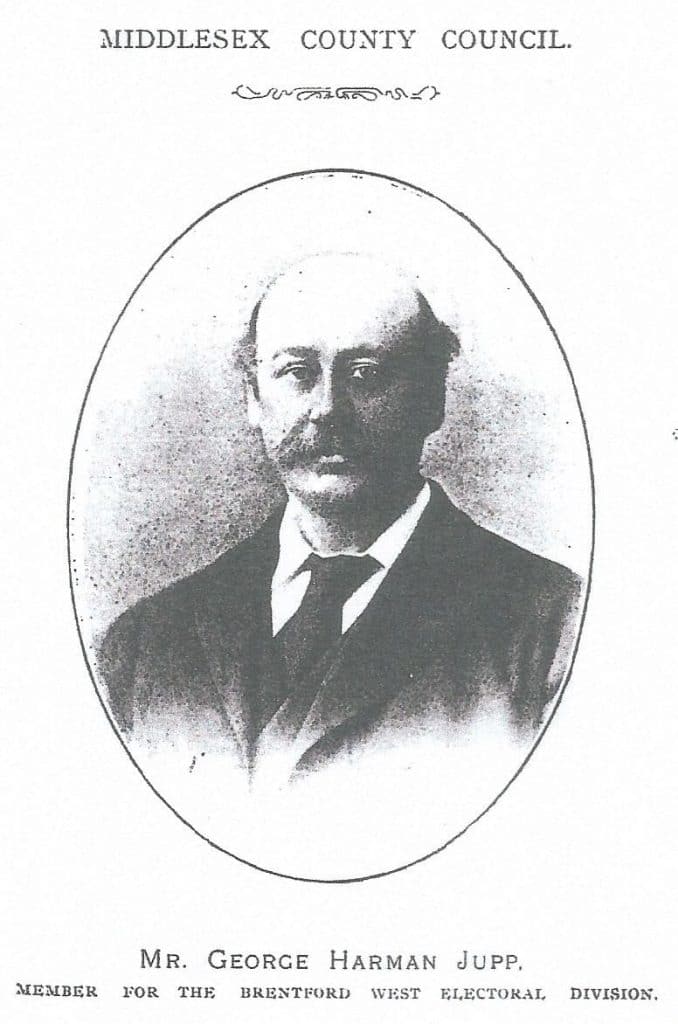

George Harman Jupp takes over the running of the business in 1881. French and Jupps now employs 66 men.

1887

1889

David Jupp purchased the maltings of H.A.& D Taylor in Stanstead Abbotts. Parts of the site dated back to before 1750. H.A & D Taylor continued in business elsewhere in Bishops Stortford and Sawbridgeworth.

1896

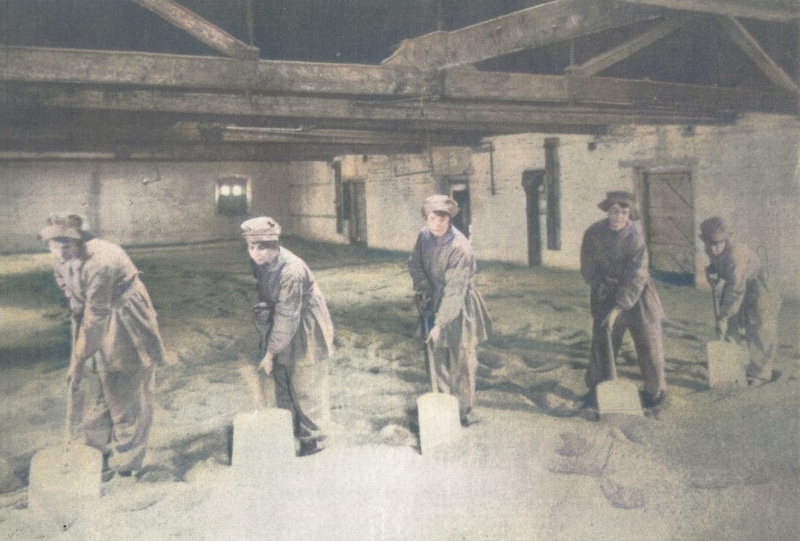

Other sites were subsequently purchased in Stanstead Abbotts and the whole enterprise moved there in this year. Cottages were built to house the employees who relocated from London. Barley was malted at one end of the village (on the present site), and the lightly kilned malt was placed in bags and taken by horse and cart to a maltings at the other end of the village, by St Margaret’s Station, where it was roasted.

1903

1914

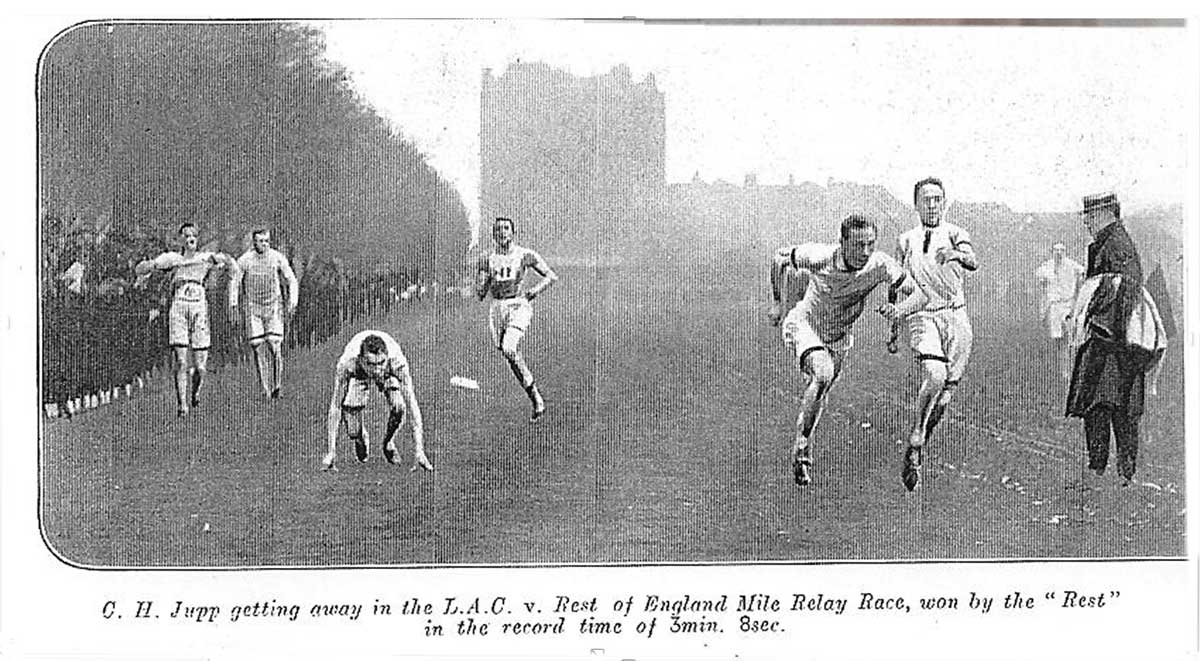

Claude Jupp becomes Chairman. In the early 1900’s Claude was the ‘fastest man’ in England over the new distance of 220 yards, winning the 1906 National Championships in a time of 22.6 seconds

1939

Due to the outbreak of the second world war, women return to the maltings to keep it in operation.

1963

1964

1966

1968

Photo: Left – Claude Jupp , Right – Ronnie Jupp

Mr Ronnie Jupp became chairman after taking over from his father, Claude.

1980

Production trebles with the advancement in technology and automation.

1987

The three Barth roasting drums were installed, two for Crystal malt production one for patent malts.

1990

Saw the arrival of no 4 germination drum which was so large it had to be brought with a police escort.

1994

2000

2006-2007

A roasting drum was bought from Guinness Park Royal Brewery in London, originally for spare parts but was soon put into commission roasting patent malts as the business grew.

2010

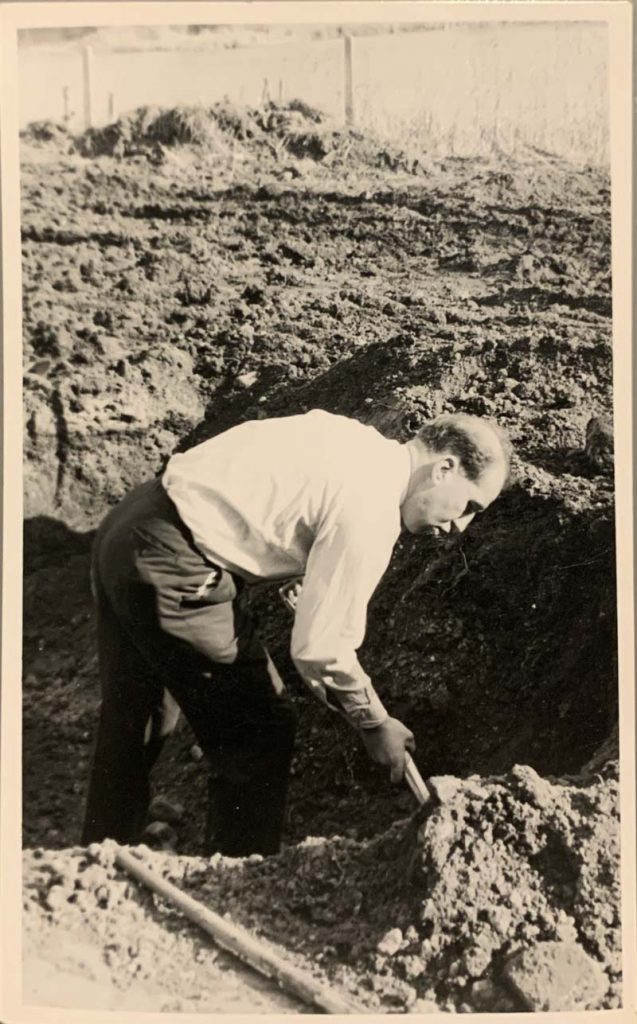

Always ready to roll up his sleeves throughout his 60 dedicated years of employment, Guy Horlock retires as Chairman after transforming the business to ensure its long-lasting legacy

2019

With porters and distinctive fine ales growing in popularity, French & Jupps proudly launches its “Light Chocolate” Malt.

2020

Photo: Left – Paul King (MD) , Right – David Jupp (Chairman)

David Jupp retires as Managing Director and continues over 330 year of family involvement by becoming the new Chairman of French & Jupps.

We’d love to become part of your journey and for you to become part of our story.

If you are looking to create your project using the finest malt with beautiful flavours and aromas, please get in touch,

French & Jupps Ltd, Roydon Road, Stanstead Abbotts, Herts, SG12 8HG

Registered Company No. 00165116

To learn about the journey from field to glass and more detailed explanation of the malting process click below.

Proudly delivering outstanding quality and services for centuries to come.

We pride ourselves in:

Producing the finest quality speciality malts

Providing an inspiring environment for businesses to develop and grow

Supporting the community and local youth programmes

Family owned and driven by core family values.

We are: One team, supportive, honest, respectful and care greatly about our community, local talented youth and the environment.

French & Jupps Ltd, Roydon Road, Stanstead Abbotts, Herts, SG12 8HG