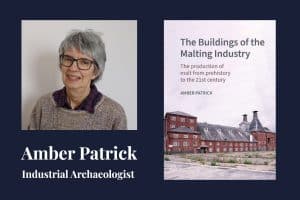

French & Jupps and The Buildings of the Malting Industry

Industrial Archaeologist Amber Patrick explores the history of the oldest family-owned malting company in Britain, French & Jupps. We’re proud to present the research for her book The Buildings of the Malting Industry published by Historic England.